Innovative R&D Infrastructure

The research conducted in CCTW is possible both in the laboratory, large laboratory scale up to PDU which increases the commercial potential of the technologies researched in CCTW.

The research conducted in CCTW is possible both in the laboratory, large laboratory scale up to PDU which increases the commercial potential of the technologies researched in CCTW.

The Department of Energy Saving and Air Protection is a part of the Clean Coal Technology Centre (CCTC) created within the structure of the Central Mining Institute – one of the largest R&D institutes in Poland. The research infrastructure of the Department, covering both the laboratory scale and pilot scale installations, make it applicable in a wide range of research fields, in particularly related but not limited to:

• coal processing and utilization, with a focus on clean coal technologies

• characterization and utilization of materials in energy, environmental engineering and chemical synthesis sectors

• waste valorization

• carbon dioxide capture and utilization

• modelling of multi-dimensional data sets

We are open to cooperation with industrial and academic environment taking into consideration the specific needs of our potential partners.

The High-Pressure Thermogravimetric Analyzer installation coupled with mass spectrometer allows the experimental verification of processes of thermochemical conversion of solid fuels including fossil fuels, biomass and wastes. The gaseous media applied include air, oxygen, carbon dioxide and nitrogen. It operates under isothermal and dynamic conditions. The maximum operating temperature is 1350ºC at the atmospheric pressure and 1100ºC at the maximum operating pressure of 4 MPa.

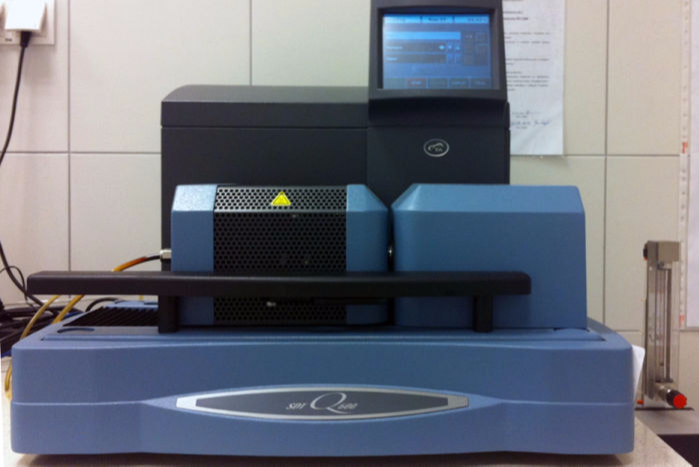

The Differential Scanning Calorimeter (DSC) determines the temperature and heat flow associated with material transitions as a function of time and temperature. It also provides quantitative and qualitative data on endothermic (heat absorption) and exothermic (heat evolution) processes of materials during physical transitions that are caused by phase changes, melting, oxidation, and other heat-related changes. The operating temperature is from -90 to 550°C.

The Thermogravimetric Analyzer provides simultaneous measurement of weight change (TGA) and true differential heat flow (DSC) on the same sample. The temperature range is from ambient to 1500°C, and the heating rate is from 0.1 to 100°C/min. The applicable gaseous media include nitrogen, argon, helium, air, oxygen and carbon dioxide.

The Autosorb iQ analyzer with extended low pressure capability is applicable in the specific surface area, pore volume and pore size distribution measurements. The pore size range measured is from 0.35 to 500 nm, the specific surface from 0.0005 m2/g and the total pore volume from 0.0001 cm3/g.

The Infrared Spectrometer with Fourier Transformation provides for measurements of spectra in the entire infrared range: near (NIR), middle (Mid-IR) and far (FIR) and is applicable for solid, liquid and gaseous samples characterization.

Sources: tungsten (27 000 – 2 000 cm-1) and ceramic (9 600 – 20 cm-1)

Beamsplitters: Ge/KBr for 7 800-350 cm-1, far-IR (700-15 cm-1) and Si/CaF2 (14 500-1 200 cm-1)

Detectors: DLaTGS with KBr window (12 000-350 cm-1), MCT-A cooled with liquid nitrogen (11 700-600 cm-1), DLaTGS/PE (700-50 cm-1)

Accessories:

1. Transmittance accessory – KBr/HDPE pellets, liquids – demountable cuvette with different distance (region of mid IR), gas cuvette 0,75 l; optical path length: 1,5 m to 8 m (region of mid IR)

2. Diffuse reflectance accessory (DRIFT) with the Praying Mantis High Temperature Reaction Chamber – collecting series of spectra under controlled temperature, rate of heating and pressure. Ranges: from room temp. to 900°C under vacuum; from the vacuum 10-6 torr to the pressure 2 atm; samples: powders; range of mid IR

3. Integrating sphere NIR with integrated detector InGaAs and sapphire window

4. Attenuated Total Reflectance (ATR) – range of far and mid IR 10 000 – 55 cm-1; diamond crystal; single reflection

Software: OMNIC 9, OMNIC Specta, TQ Analyst and rich libraries of spectra.

The pilot-scale moving bed reactor is designed to perform large scale tests on gasification of solid fuels at temperatures up to 1200ºC and under pressure up to 3 MPa. It gives the possibility to test the thermochemical conversion processes at larger scale, thus reducing possible scale-effects. The gaseous media like air, oxygen, and CO2 may be applied.

Preparation of expertises, techno-economic analyses, feasibility studies as well as process designs of gasification and liquefaction of coal.

- laboratory stands for pressurised and pressureless gasification in reactors simulating coal seam;

- laboratory stand for research on direct coal hydrogenation;

- laboratory stand for research on purification and separation of process gases fromgassification applying membranes PSA method;

- testing stand for analysis of gas combustion in gas engines and turbines;

- underground testing range for researching the Underground Coal Gasification process, located in the seam no. 310 and equipped with infrastructure which allows to feed the georeactors with gasification agents as well as product recovery system.

Research infrastructure allows the comprehensive studying and run of processes in multiple scales – from basic laboratory scale research, through a bench scale studies up to pilot scale processes performance.

Downloadable PDF here.